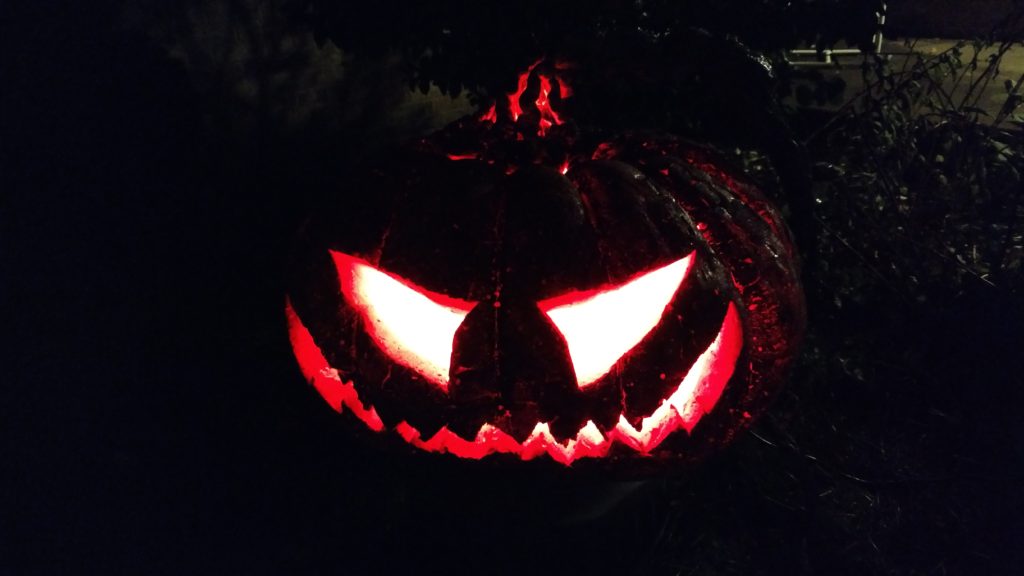

Step 1 – Making a Great Pumpkin

How many cans of spray foam does it take to cover a garbage bag full of shredded newspaper with a thick enough surface that you’ll be able to carve a reasonable facsimile of a real, live pumpkin? I lost count. A dozen? This was a messy job. I did discover however, that Great Stuff (red can) does NOT stick to the really thick vapor barrier plastic. (This knowledge came in handy later).

I always imagined Peter having a very squat shape, and I tried to make the plastic bag resemble that before coating it, but the more foam it accumulated, the more it sagged. In the end I just let it dry in apple form, then cut the middle out before carving it down with a bread knife and rasp. Important safety tip…if you value your tools, you have to let the foam cure. Take as long as you need. I actually kept the foam ball around for a year before carving it.

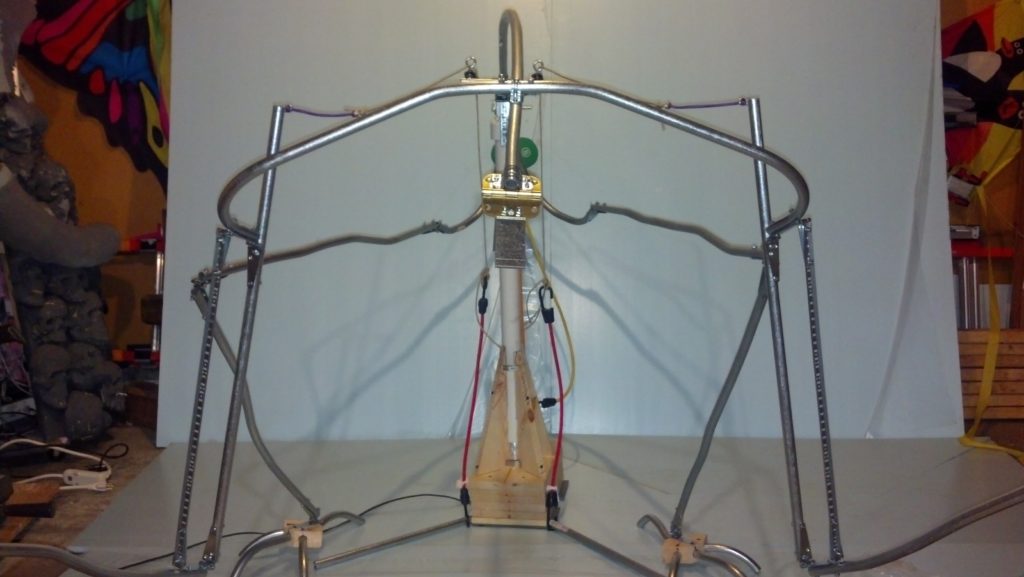

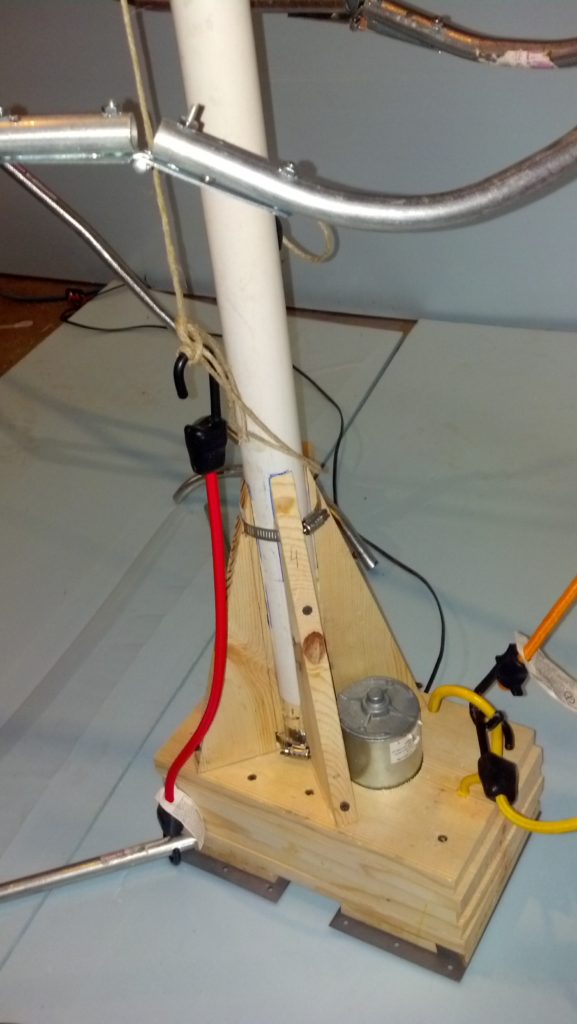

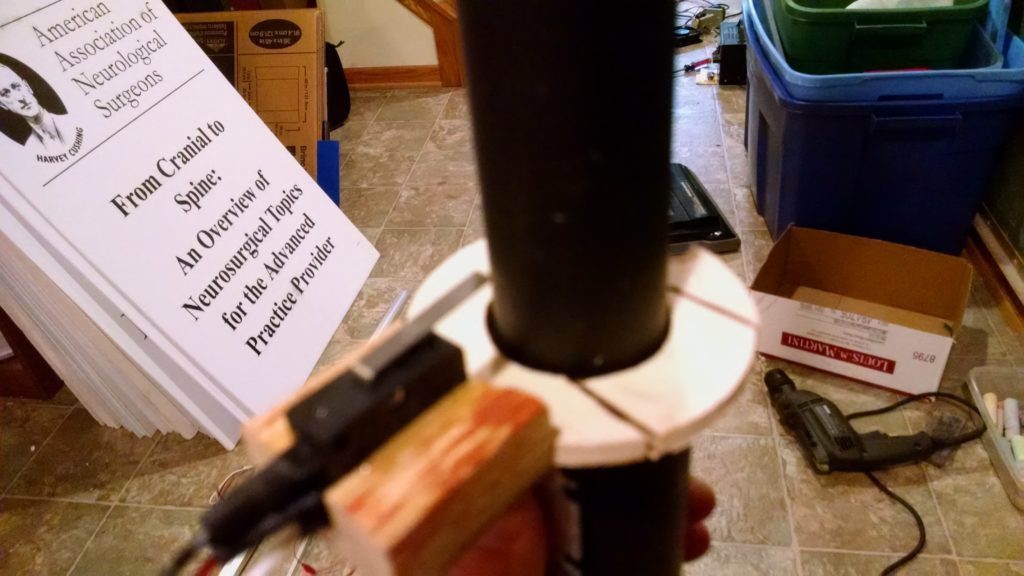

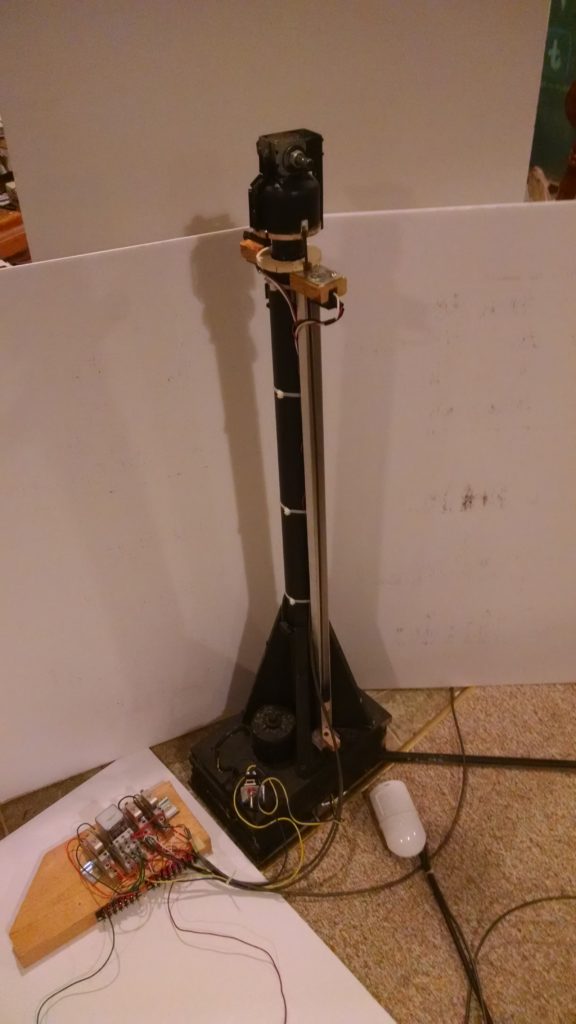

Step 2 : Building the frame…

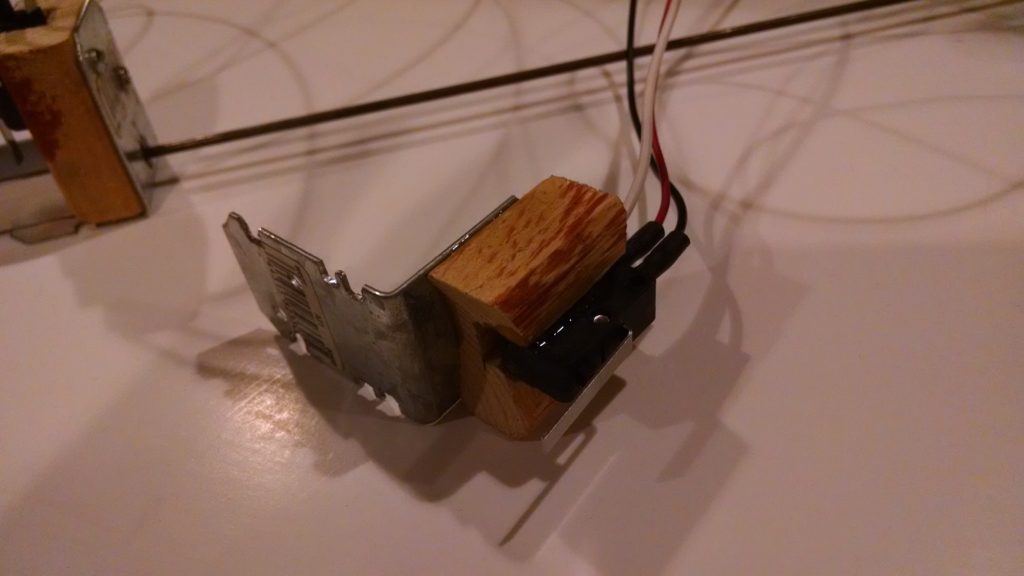

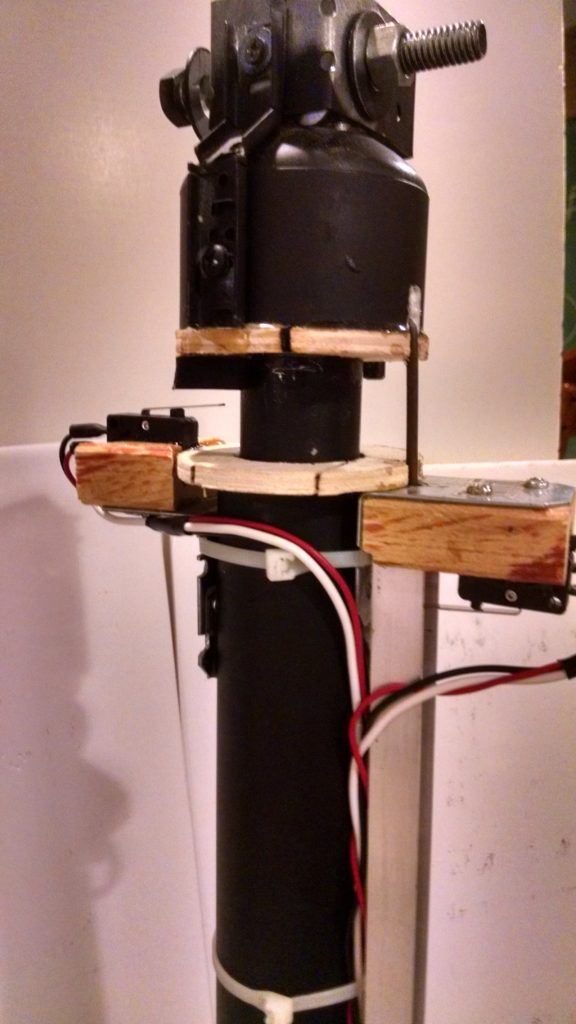

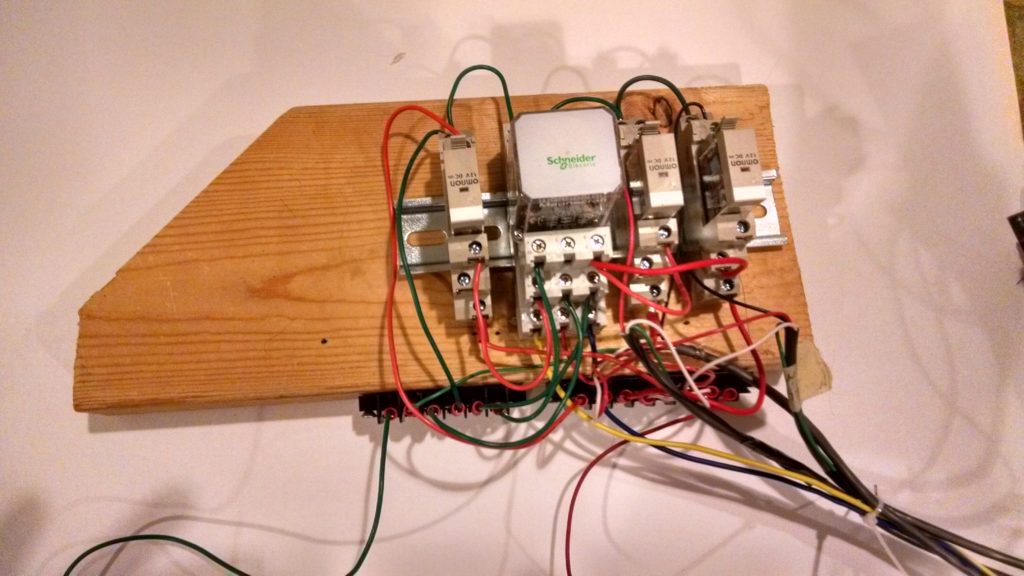

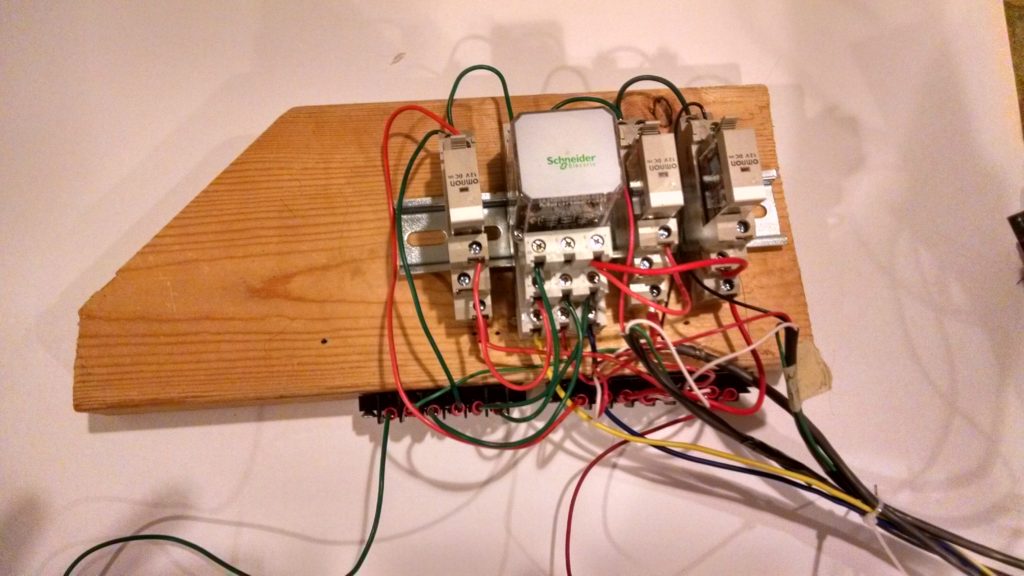

Step 3 : How will I control the actuator?

Step 4: Peter takes form

Step 5 : Peter comes outside

Step 6 : Cry

So Peter worked almost flawlessly in the garage – Except for the positioning of the pumpkin-head as it lifted off the stump. And the touchdown of the pumpkin-head back onto the stump on descent.

But other than that, he was impressive and imposing. And I couldn’t wait to show him off at the Halloween Party.

Unfortunately, it was windy that night, right out of the south and essentially blowing downhill, perpendicular to the crouched prop. Unfortunately, Peter wasn’t sitting on level ground…he was canted just a bit downhill.

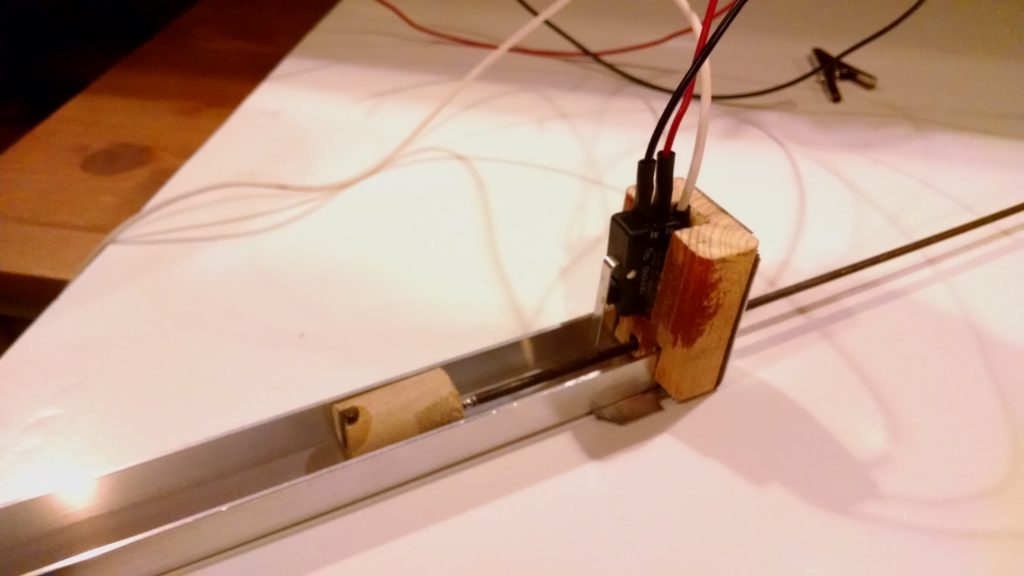

So here’s what happened, on Peter’s inaugural deployment. I tripped the motion sensor, and Peter’s torso began to climb upward. The pumpkin head tilted downward on the stump until the force of upward movement exceeded the force of gravity. A gust of wind shot out of the south, and instead of peter falling over (as I feared), he ROTATED with the wind, his head now dragging along the ground in a drunken leer to his left. As he rotated, this put additional pull on the back bungee cords, which caused his spine to tilt back, raising the pumpkin skyward (but facing 90 degrees to port), like a huge-headed weather vane. The control rod hit full extension, the wine-cork hit the trigger switch at the top of the channel, and the motor reversed, now retracting. As the motor came down, I kept hearing strange pinging sounds coming from the top of the motor. Peter was still facing downhill, his legs twisted like he was trying to sit back down cross-legged. But that wasn’t really the problem. The pinging sound was the control rod … the one with the cork on it that would touch down on the limit switch… that rod had bent back and forth on itself as it tried to find a path through the channel, that was now twisted 90 degrees away from it. The motor ground to a halt, no longer able to advance past the twisted steel rod, and unable to reach its cutoff safety switch. I had to yank the power cord out to stop it. He never went up again.

Essentially, the control rod was responsible for two things: 1. limiting rotation, and 2. stopping the rise or fall before it hit the end of the linear actuator.

2016 Update

In 2016 I tried to fix Peter, focusing primarily on the most vexing issue: leveling the head. I envisioned something like two mercury switches that could cause a motor to pull back when the head tipped too far forward, and push forward when the head leaned too far back. I found two magnetic reed switches instead. Execution was clumsy. The ‘level’ magnet would swing dramatically back and forth, essentially freaking out the motor. Sometimes it would get so freaked out it went backward, and almost ripped the pumpkin right off Peter’s shoulders.

At any rate, the mechanism didn’t work, and Peter stayed in the garage.

Plus, here’s a great example of poor planning. Four lantern batteries attached in series, because I bought 24-volt relays a long time ago, and that’s all I had laying around… because, seriously… who keeps 24-volt DC transformers around. The reason I had those was because I have a device controller from a past life that happens to pump out 24v DC. Unfortunately, the device has long since been retired.